[Link to the original newsletter]

Summary:

Another exciting year has passed. Thanks for your patience! This is the quick summary of what aponix has done so far in 2019.

We have been active to show the aponix vertical barrel at trade shows in still mainly in Europe. Quite some testing units have been shipped (see locations). Thanks to all active users!

Our focus has been to improve and extend our parts. Logistics and exporting capabilities have been extended too to make quoting, ordering and shipping easier.

There are many interesting perspectives evolving at the moment, that we will certainly reveal in our next newsletter(s). Stay tuned and have your daily hyperlocal bowl of greens. It is good for you!

1. The new one netpot piece is available

The new one netpot piece will be available from mid September and will give you more flexibility with regard to the configuration of the plant spacing on the vertical barrel surface. Evenly equipped with only these pieces your plants can become 30cm wide and 30cm high. In combination with the other existing pieces like. the closed spacer and the piece with two net pot inserts you have now more flexibility. You can find more images on the target page.

One example of the continuous improvements we are implementing: On the left image you can see the ‘teeth’ behind the netpot have been modified to make sure the liquid can not run to the front side of the net pot anymore. That caused some liquid to reach the outside in the past.

We also extended our website and added the metrics more visually on a metrics page.

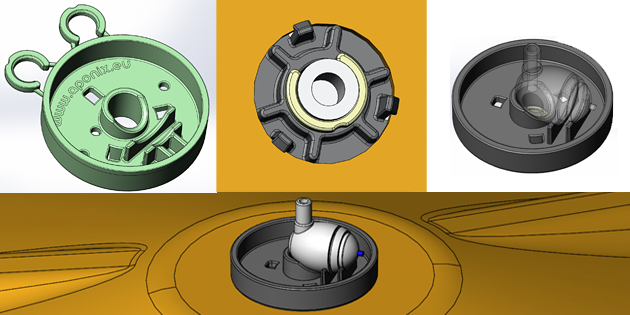

2. Another irrigation option: The Netafim-aponix adapter

To make the irrigation more versatile and give more options and robustness regarding flow rates, we are currently building a Netafim-aponix adapter to be clipped to our top lid. It holds a Netafim drip stop component where a Netafim VibroNet or a SpinNet sprayer (and others) can be attached. This enables the use of 7/4mm (sometimes also called 6mm) micro tubing with >2bars pressure for irrigation at a flow rate of 40 or 70l/h. This is the perfect flow rate for aponix units.

It is planned to have the adapter available as of November 2019. Here is a preview on our Future Pieces page (2nd item from the top). You can also see some 3D renderings in this facebook post.

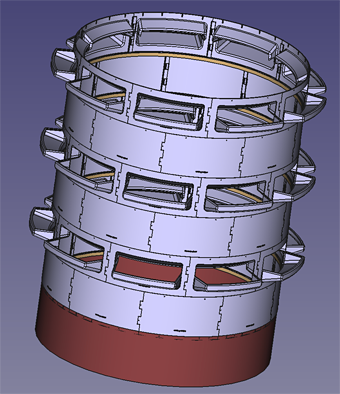

3. A vandalism proof substrate based City XL version is coming

Another product based on the vertical barrel concept has been co-created – a XL City version of the substrate based version. In cooperation with the City of Heidelberg we have been watching and learning the requirements building prototypes using our existing smaller substrate based pieces and designed a much larger and more robust version.

Another product based on the vertical barrel concept has been co-created – a XL City version of the substrate based version. In cooperation with the City of Heidelberg we have been watching and learning the requirements building prototypes using our existing smaller substrate based pieces and designed a much larger and more robust version.

Setting it up requires integration into other components. In our case this will be a large (square) base that can hold 100+ liters of water plus a concrete base inside. Another custom round metal base is built to start with the base ring segment and subsequent ring segments.

Ringsegments will use 9 pieces in this case and they can optionally be combined by using screws or rivets. The prototype also had an integrated solar panel that powers a small pump to make sure each unit is independently irrigated once a day. Check out the prototype at an event in June 2019 ‘Lebendiger Neckar‘ showcasing the autonomous solar irrigated substrate version.

If you are involved in city planning and you think this could be interesting equipment for your city too, please contact us or forward to your colleagues. We are looking for test cases!

4. There is a technical user group

With more users all over the world we opened a new technical user group on Facebook to show special solutions or setups for the benefit of active users.

If you are an active user we like to invite you to use this group to show others how you solved certain issues you faced the pragmatic gardener style.

5. Shows 2019

Trade shows with presence of aponix this year:

- IPM 2019, Essen, 22. – 25. Jan 2019

- HortiContact GO 2019, Gorinchem, 19. – 21. Feb 2019

- BuGa (Bundes-Gartenschau), Heilbronn, 17. Apr – 6. Oct 2019

- GreenTech 2019, Amsterdam, 7. – 10. June 2019

Past events, media presence and interviews can also be found in our news section and on our Facebook page.

6. TASPO award ‘Innovative Product’

The aponix vertical barrel is very proud to be amongs the 5 finalists of the German TASPO awards in the ‘Innovative Product of the Year’ category.

The winner will be announced on the 25th Oct in Berlin at the 14th TASPO Awards Gala.

7. Test package 7 ring segments

7. Test package 7 ring segments

For folks who like to test run a smaller setup 7 ring segments high / using one (41 plants) or two netpot (82 plants) piece.

Materials are always on stock and can be ordered and shipped any time. Parts pricing and shipping cost for different regions can be found on the page.

Let us know if you like to test a different setup.

8. Help! Google reviews!

8. Help! Google reviews!

We found out that Google reviews can have quite an impact. So we like to ask our existing friends and users who use our equipment successfully or like the responsiveness, support and service aponix delivers to leave us a Google review on any aspect they like the most.

It will be of great value!

The review is also a good source to browse production images.

9. Value adding resellers wanted

9. Value adding resellers wanted

We are still looking for value adding resellers. If you are a horticulture consultant or active in plant production giving advice and recommendations to clients on how to plan, setup and equip their farms this might be for you.

Resellers commit to a territory/area, address a defined target group or application and become the face to their own customers regarding aponix components they offer.

10. Alternative to racks / scissor lifts

The mission of aponix is to make hyperlocal edible plant production easy, productive and robust – for commercial operations running urban farms and for the advanced prosumer or hobby enthusiast. The aponix parts can be used to set up grow spaces for both types of applications in very flexible and modular ways.

The idea is to pose an alternative to building racks or go super high with thinner tower solutions and still be able to use natural sunlight and reach plants with standard mechanical equipment like rail trolleys instead of using a scissor lift.

Remember: Height = number of grow spaces = always variable.

Plant spacing and plant shape = configurable.

No fixed elements (tables or racks) needed.