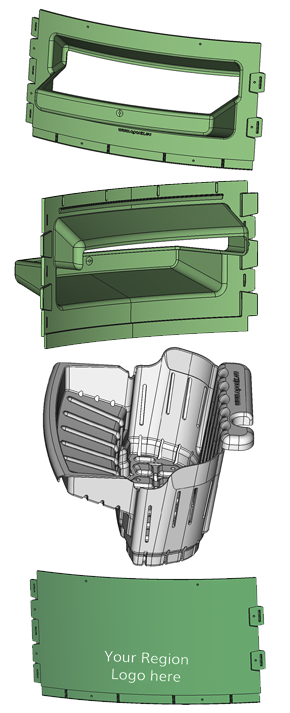

This is another much larger and rigid version to make the aponix substrate vertical barrel idea available also for public spaces – there is a vandalism and fire proof version and a ASA white one. We call it the City XL version. It uses 9 ring segments per level (diameter 95cm) and is much more robust. It requires manual integration into a larger urban planting context along for example roads or bicycle lanes for example. Pieces can be fixed/combined using metal rivets or also metal inlays inside and rivets in combination to make have a solid structure.

This is another much larger and rigid version to make the aponix substrate vertical barrel idea available also for public spaces – there is a vandalism and fire proof version and a ASA white one. We call it the City XL version. It uses 9 ring segments per level (diameter 95cm) and is much more robust. It requires manual integration into a larger urban planting context along for example roads or bicycle lanes for example. Pieces can be fixed/combined using metal rivets or also metal inlays inside and rivets in combination to make have a solid structure.

On the right you can see how it looked as a prototype in an integrated way built from our existing smaller ‘white’ substrate shelf pieces.

The Shelf Piece is available as a small batch. The other parts (Closed Piece with optional logo and optional Planting Insert)

Pieces need to be integrated into a larger context with a base, irrigation and internal logic. The idea is to have building blocks that have the following properties:

- It can be made for public spaces with Flammability UL94 tested and rated V-2 material, that will not create sharp edges when it breaks. Standard material would be ASA white with very high UV stability.

- Can be tightened and combined into al rigid large structure using screws or rivets if required. There are different levels of stability.

- Can be assembled and disassembled at the end of the season to recycle the substrate more easily.

- Can be prepared off-site and be moved with a fork lift to the exhibition location.

- Is made from food safe material to also grow edible plants in public spaces (drastically reduces vandalism).

- The closed part can be custom made with a regional logo. For custom batches the color is also a variable.

- The setup can be filled with substrate. Optionally there is a planting insert, that is mounted from the inside with which the inside of the setup can be kept clean for logic.

Images of a prototype setup using only the City-XL Shelf element planted with beans and corn.

Please let us know if you would be interested to learn more about our City XL Vertical Barrels system! We are looking for pilot projects. Please note that, we only provide the ring segment pieces and every setup will need to be integrated setup in an individual way. You will need to build a round metal base, fill the interior with substrate a center spacing tube or using our Plant Inserts, add irrigation logic or connect it to a natural rainwater supply etc.