This publication is meant for free download, redistribution on 3rd party channels and usage for articles in magazines and as news:

Files:

The aponix vertical barrel is a new concept that facilitates setup of high density grow spaces for soil-less production by expanding the NFT hydroponics concept into the 3rd dimension in a very flexible way. It is especially designed for urban farming facilities operating on limited space.

The concept uses sturdy, compact and simple parts that can be integrated smoothly into the daily planting, maintenance and harvesting routines in medium-sized urban farming facilities. There are no fixed structures necessary for the setup, like tables or racks and the barrels can be positioned and moved easily to provide flexibility in a growing operation. The system is most efficient when the barrels are arranged in lines with a gravity pipe or gutter below them that cycles the liquid from the irrigation back to the central reservoir.

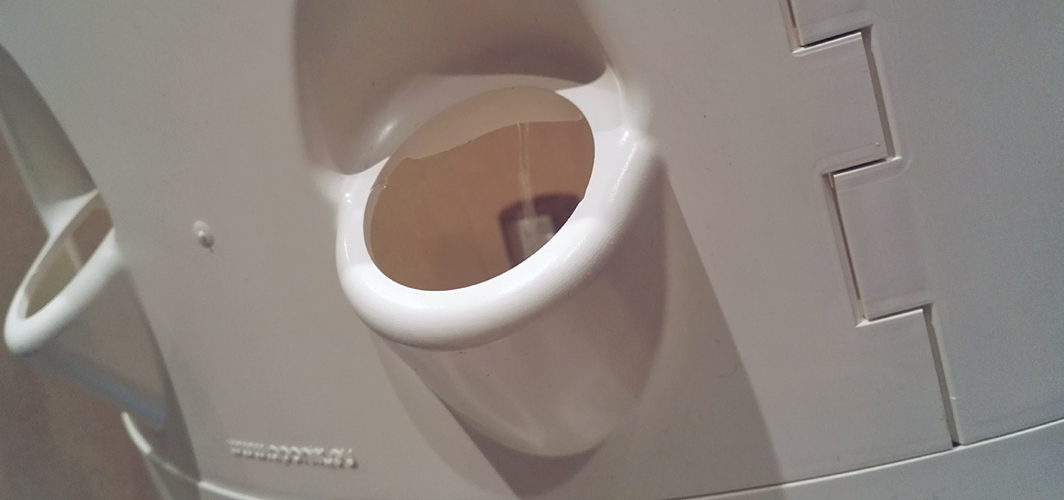

Cultivation area is on the outside surface a barrel that has adjustable height by adding more grow spaces. The barrel is basically a one lego-like part that is 1/6th of a ring segment of a barrel. Each of the parts provides grow adapters. Six of these parts are assembled into a barrel ring segment and any number of ring segments are then stacked as high as space allows for the cultivation of a crop. Each barrel is built on a solid base and sealed on top with a lid that includes a point of irrigation using a simple sprinkler, spray nozzle or even an individual irrigation solution. The entire barrel can also be used as a hanging system by adding nylon ribbons to the top lid and hanging it on a swivel hook.

Inside the barrel the liquid is distributed evenly from the highest point to the inside surface of the barrel where it moves down the barrel while being diverted by a wing structure that directs the liquid to each root zone of the plants. Each plant is basically a pre-grown seedling sitting in a 2” net pot. Many barrels can be connected in line and be powered by a central reservoir with organic or mineral liquid nutrient solution and a pump for irrigation.

After the harvest of a barrel, ring segments can be easily un-stacked, power-washed, restacked and replanted immediately. This feature offers easy maintenance compared to other tower systems on the market. Operators will do this many times during the lifetime of the equipment.

Production versions of the barrel parts are manufactured in Germany with high quality materials and are now available. The new parts contain a series of improvements gathered from feedback provided by professional users and research facilities that tested the initial prototype barrels for over 2 years. The current grow adapters of the 1/6th parts provide two 2” net pot inserts which can be used to grow herbs, lettuce or strawberries.

Dimensions

One barrel ring segment provides 12 grow spaces and has a height of approximately 6 inches. The diameter of the barrel is 22.44 inces. The standing base has a diameter of just under 3 feet. With the two 2” net pot adapters each plant has a horizontal space approximately 6 inches and vertical space approximately 12 inches up/down. A barrel with 14 ring segments provides 168 grow spaces and has a height just under 8 feet 9 inches.

More versatile adapters for larger crops are being developed including a 1/6th part with one central net pot insert and a completely closed part, that can be used to assemble the ring segments of barrels according to the size of a crop. A soil-based version will be available in late Summer 2017. With the new parts coming, the concept can also provide the setup for a standalone soil-less barrel and soil-based barrels or even be used as water filter for grey-water in smart communities or swimming ponds.

Aponix is expanding and is currently looking for sales and manufacturing partners.

For more information email hello@aponix.eu, visit Aponix.eu or Facebook.com/aponix.eu.