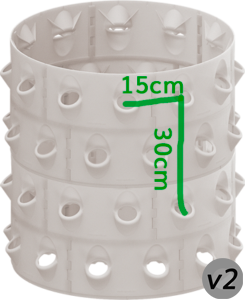

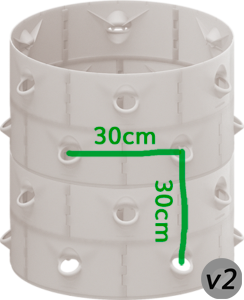

In order to configure for the highest possible plant density you would use the V2 two-netpot piece / V3 two-netpot piece the plant spacing is: vertically 30cm, horizontally 15cm. You can always use spacer pieces for larger plants either to just have one complete closed ring segment or alternate with them. In V2 there was a piece with one centered net pot. Using the one netpot piece vertical space can be increased to 30cm between your plants.

In order to configure for the highest possible plant density you would use the V2 two-netpot piece / V3 two-netpot piece the plant spacing is: vertically 30cm, horizontally 15cm. You can always use spacer pieces for larger plants either to just have one complete closed ring segment or alternate with them. In V2 there was a piece with one centered net pot. Using the one netpot piece vertical space can be increased to 30cm between your plants.

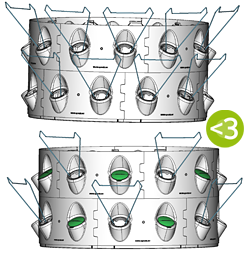

In V3 you use the general two net pot piece and close one or both of the grow spaces using a grow space cover.

The diameter of a vertical barrel is always 57cm (circumference of 180cm/Pi). We always use 6 ring segment parts to assemble one full stackable ring segment.

For V2 there are 4 different positions to stack the ring segments on top of each other. For V3 there are 2. Each ring segment adds 15cm of high. The number of ring segments you stack is always variable.

V2 and V3 ring segments can be stacked. But you can not mix V2 and V3 ring segment pieces in the same ring segment, since the connection has been changed.

With the sprinkler dome lid for pressure irrigation and our waterbuffer for pressure-less irrigation the flow rates have become more flexible with V3 compared to V2 setups.

We always run irrigation cycles on a timer, usually max once every hour during daytime and only 2-3 times during night time. Please check section A) on the configuration page.

Example barrel: 12 ring segments (built from 72 adapter parts) plus dome lid irrigation and base provides 144 grow spaces and is 2.0m high. if you add 2 more ring segments height (you need 12 more ring segment pieces) will be 2.3m providing 168 grow spaces. Irrigation does not change with that change, since we still have gravity for the additional 30cm vertical drip irrigation. This is done using the inside wing system built into the parts.

In order to calculate/plan the total number of grow spaces (density) we recommend you think about how to organize multiple barrel units in your cultivation area and start by calculating 3sqm per unit. See our integration section for examples and more details.