Available as of end 2019: The Netafim-aponix adapter

Please check the Netafim adapter product page.

Available as of 2020: Substrate based building blocks for public spaces – City-XL version

Available as of 2020: Substrate based building blocks for public spaces – City-XL version

Please check our dedicated page for the City XL Vertical Barrel.

From here other extensions are possible like autonomous irrigation using a solar panel, a small submerged pump, a timer and an integrated battery (see image below).

Please let us know if you would be interested in testing or using these city grade pieces and what your ideas for an integrations or extensions you have!

Available as of August 2020: The Lid-base

Please check the Lid-base product page.

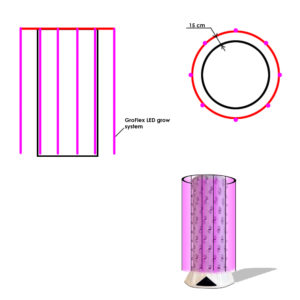

Supplemental or full artificial lighting is a challenge

Because of the shape and nature of one or more vertical cylinders/barrels of variable height, adding radiation to setups is tricky.

One solution would be just surround the barrel surface with your plants with flexible LED ribbons like they are used in shipping containers using ZipGrow towers.

If you are operating in a greenhouse and you are in a location with enough radiation, diffusing glaring will do the trick. But not everybody has a nice greenhouse at hand.

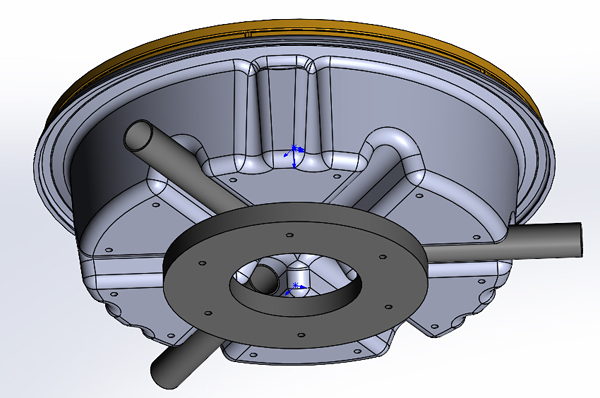

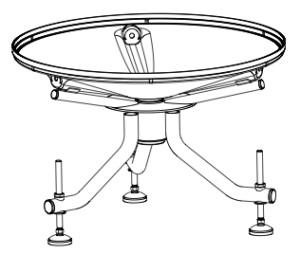

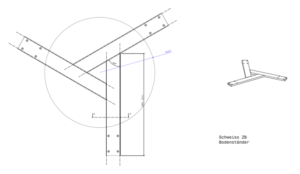

This is why we will come up with a rotation solution for the vertical barrels. The construction is already done and looks like in the construction on the right. There are 2 rotational ‘propellers’ using a gliding disc. We can use the top lid as base just like in the hanging version of the vertical barrel. On longer production lines there might be a need to elevate the barrels in order to catch the liquid draining in the middle with enough slope for the gravity based circulation.

Once we can rotate the barrels, we can use the standard lights again.

Roller base to move around the closed base

Using the closed base in substrate based barrel setups or for soilless standalone vertical barrels is much more fun if you can also move these heavy objects around. For this purpose the closed base already has kind an area integrated that will hold on to a triangle metal base. Currently we only offer the construction for users so they can weld them locally themselves. See PDF on the manual page. The plan is to get this piece also in series and offer it for people who do not want to weld themselves and equip the thing with 3 heavy weight rolls. This will also make the filled and planted soil based barrels be transportable by a forklift. Which might be very useful if you like to handle many of them.

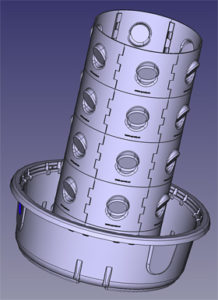

Inside logic for the substrate based vertical barrel

We often hear that the amount of substrate required to fill a vertical substrate based barrel is too much. True, that is why we always put a wire mesh inside and used it as draining column. The substrate/compost is the only filled into the space between the column and the shelves.

In order to make things more versatile and professional to set up, there will be another lego-part to assemble the inside. Using 3 pieces in that case to assemble a ring segment. The closed base already has a line engraved that will keep the inside column in place. With this piece you can grow your inside column with the usual ring segments.

You can leave the inside completely empty or fill it with hydroton or whatever you like – use it for your own irrigation solution, vermicomposting etc.