Here are some more questions and answers. This is a living overview of questions and answers about the barrels we answer frequently. In order to understand the aponix vertical barrel and its modularity please make sure you take a closer look at our vertical barrel configuration page.

If you are interested in bundles or pieces you can make a list of items and send it via our request a quote function along with your questions.

FAQ

-

A: The aponix vertical barrel started as an experiment in 2014, and it has been tested and reviewed by independent professional growers for the last two years based on the first injection molded prototype parts. The concept works very well and parts are being manufactured in larger numbers including all improvements from along the way since November 2016 for the first soil-less parts and extended until Summer 2017 into a soil-based version too. As of 2020 Version 3 was created and many very useful items like our reusable plug pot with optional metal trellis insert or our netafim spraying adapter or the sprinkler dome lid. It should be considered professional horticulture equipment mainly targeted at urban farms, which does not necessarily mean ‘small’ operations. It is definitely different than any other hobby towers out there.

The main driver for the simplistic and robust design was the fact that there are too many poorly engineered and cheap solutions out there, which in practice are very hard to use constantly and in the end become very expensive and unreliable.

Several users are currently testing/planning it to be integrated into larger production facilities >50 and >100 vertical barrels.

-

A: The aponix vertical barrel is a new kind of vertical component (3D-NFT) to which also the production processes will be different from the known components like horizontal NFTs etc. People planning a production facility will also have to consider the day-to-day work like planting, maintenance, cleaning and harvesting in the overall calculation and planning. We always recommend to get a bunch of testing barrels upfront and run an few cycles in order to get confident with it and know your processes then. Also ventilation is much more efficient using aponix barrels if it is done from the top in greenhouses for example.

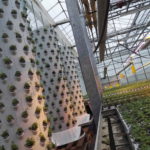

The first growing cycle of the staff at LVG Heidelberg managed to have it look like you can see in the gallery on this page. Here you can find more spots where you already can find aponix vertical barrels. More research facilities are using them since 2017.

-

A: Yes!

- Assumption: Your type of lettuce will be grown for 28 days until harvest.

- You will need 28000 grow spaces to harvest 1000 pieces a day on average.

- Let’s add a failure rate to that so you really get your 1000 out of the system.

- If we use standing aponix barrels with 12 ring segments each (height 2,1 meters) using the 2x 2 inch net pot ‘adapters’, we will have 144 grow spaces per barrel.

- Using 210 of these 12-ring barrels would result in 30240 grow spaces.

- For each barrel (barrel diameter is 57 centimeters, the base needs a 88 centimeter circle space) we recommend 2.5 to 3 squaremeters space on average if we arrange the barrels like shown in this spacy sketch on the bottom of the page.

- Your required net cultivation area for the 1000 lettuces per day would then be between 525 and 630 sqm. Of course you could go much more dense, but we would recommend to gain experience first. Higher plant density also means that potential pest will spread easier/faster and needs to be tightly monitored and managed.

- Counter question: How many heads of lettuce do you get per day if you use 13 ring segment high barrels instead of 12? You could do that any time, it adds 15 centimeters of hight and 12 grow spaces to each of your barrels, and nothing more. (Answer: 90)

-

A: Adapter parts are the pieces you assemble into ring segments of a vertical barrel. All parts are flexibly interchangeable – the concept and the way the parts get assembled will stay the same as we extend the range of adapters in the future. It will give the user more flexibility with regard to different crop sizes and also be usable the soil-less and the soil-based way. Parts are:

- The ‘main part’ providing V2 two 2-inch net pot inserts. 2″ net pots are widely available. We can provide them too, but do not need to. Please also consider our reusable plug pot.

- One broad open shelf through which the user can work with a small shovel. With this part it will be possible to build soil-based setups. We have already been experimenting with barrels attached on roller boards that are 6 ring segments high and have a wickerbed bladder with overflow inside the lowest ring segment. The rest is then filled with hydrotone and soil. Exotic test, but it works and grows a lot of plants. This version is targeting end consumers and is available since mid 2017. There will also be a special base for the soil-based version. The number of ring segments you are using is flexible.

- One completely closed part. If you plan to grow bigger plants like Kohlrabi you might not use all the grow spaces. You will also be able to use this closed part to assemble your ring segments for the soil-based version giving you more flexibility for the size of your plants. This part is available since mid 2017.

- A V2 revision part with an opening to reach inside a running barrel is also available since mid 2017.

- One centered 2 inch net pot is planned but as of May 2018 not yet available in larger series.

If you have ideas for your special adapter, please let us know.

-

A: Materials are of highest quality in materials and manufactured in Germany. Parts are supposed to be in use for many years delivering 10-14 harvesting cycles a year, being handled and cleaned after each cycle with high pressure or steam.

If you require it, you could even have your parts manufactured with food grade thermoplastics that have the explicit certificates. All our materials are of food grade quality, but without the costly certificate from the raw material vendor.

Plastics used:

- Lids and stands: PVC-U

- 1/6th parts: ASA

-

A: This depends on where you are located. Since we are currently establishing some resale and license partnerships, this can be different for for certain territories. You can always visit our ‘Request a Quote’ area and submit this list with additional text information about the destination of the parts to get an individual quotation. We ship internationally. For the real world solutions we are working with product partners.

In general you need to have some professional helping you to lay out a plan for your production facility including all the other important areas like propagation, packaging, storage, HVAC etc. Aponix provides you with the barrel components.

In case you wonder who is already using it, please take a look at the map on this page (please zoom out).

-

A: That is actually the reason we are calling our component a barrel, instead of a tower. There are many different variants of towers on the market. I few general differences are:

- Each level comes in one solid piece and has less grow spaces per level due to the smaller diameter compared to the aponix barrel.

- In some of the solutions there are different movable small parts to complete one level. And they need to be dis-assembled and re-assembled between every cleaning cycle. The aponix barrel uses 6 times the same part (the 1/6th part) that is once assembled on the setup and then left as a full ring segment for the rest of its production use. This has the advantage, that after harvesting a barrel, ring segments are just un-stacked, power-cleaned and then re-stacked and replanted. That’s it.

- Many of the tower solutions have their own reservoir and pump in their base. That is fine if you operate 1 or a bunch of them. It becomes a maintenance nightmare ++10 towers.

- You can use the aponix barrel on your terrace or balcony with soil too as soon as the ‘soil’-adapter is available.

-

A: Please check the latest version of our manuals.

-

If you like to have a cozy living room – No. Usually home users underestimate the amount of light required to grow plants successfully. Even behind a south-facing window light conditions are by far not sufficient. And running/maintaining can always result in spilled water. You will hear the liquid running on the irrigation cycles. An ideal place would be an area in your ‘living space’ where you have a lot of light and a hard floor (no carpet) that can be cleaned and dried easily, a sunroom would be ideal.

Examples

- Prototypes 2016

- Prototypes 2016

- GreenTech 2016

- Prototype China

- China, Exhibition

- Prototyping 2015

- Prototyping 2015

- Prototyping 2015

- Prototyping 2015

- Prototyping 2015

- GreenTech 2016

- Prototypes 2016

- Generation 2 2017

- Prototypes 2016

- Prototypes 2016

- Prototypes 2016

- Prototypes 2016

- Prototypes 2016

- Prototypes 2016

- GreenTech 2016

- Prototype China

- Prototyping 2015

- Prototyping 2015

- Prototyping 2015

- Prototyping 2015

- Marco

- Prototyping 2015

- Prototypes 2016

- Prototypes 2016

- Prototypes 2016

- Prototypes 2016

- Prototypes 2016

- Prototypes 2016

- Prototypes 2016

- Prototypes 2016

- Prototypes 2016

- Prototypes 2016

- Prototypes 2016

- Chennai, India

- Stuttgart 2017

- Mint production

- Seedlings 2016